At our company, we understand the importance of finding effective ways to improve the wear resistance of materials used in various applications. One of the most effective methods we have found for achieving this is through the process of zinc plating. In this

Using a lathe and pressure, metal can be moulded into the desired shape through a technique called metal spinning. This method can be applied to make a wide range of objects that serve various purposes, such as functional parts like lighting fixtures and

If you are looking to manufacture a product that requires metal as its base material, you may be wondering which is better: sheet metal vs. plate? The answer is not straightforward, as both forms of material have their own unique strengths and weaknesses.

Are you running a manufacturing business and facing challenges in keeping up with industry trends and standards? Are you struggling to optimize your production process, reduce costs, and increase profitability? If yes, then you might benefit from working with a manufacturing consultancy. In

As metal fabrication and manufacturing continue to advance, the process of cutting metal has become increasingly sophisticated. There are now several types of metal cutting processes available, each with their own unique features and benefits. In this article, we will explore 5 different

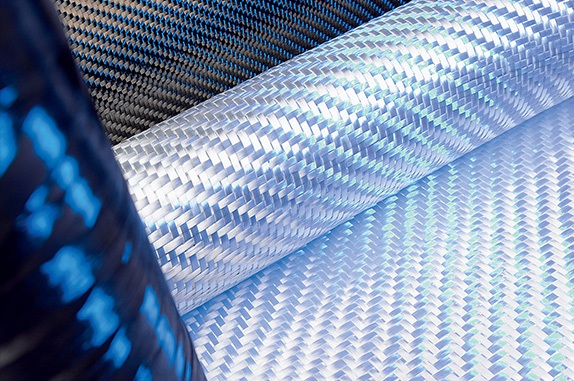

Composite materials are revolutionizing various industries, from aerospace to sporting goods. The innovative properties of composites are making them a preferred choice for many applications, including their high strength-to-weight ratio, durability, and flexibility. In this article, we will explore the latest innovations in

In today's fast-paced business world, manufacturers are continuously seeking ways to enhance their production processes and remain competitive. One such approach that has gained popularity in recent years is lean manufacturing. Lean manufacturing is a systematic approach to identifying and eliminating waste in

Manufacturing is an industry that is critical to the success of the global economy. With increasing demand for high-quality products, it is essential that manufacturers maintain high standards of quality control to ensure their products meet customer expectations. This article outlines the importance

Aluminium is a widely used material in the manufacturing industry due to its strength, lightness, and versatility. However, aluminium is prone to corrosion, which can affect its appearance and structural integrity. To overcome this issue, anodising aluminium has become a popular process in