- Head Office: Brisbane, Australia

- AUS: 1800 333 182

- INT: +61 7 3369 6442

- Download Brochure

- ABN: 48 136 482 114

Home / Welding Tables and Jigs / Welding Jigs

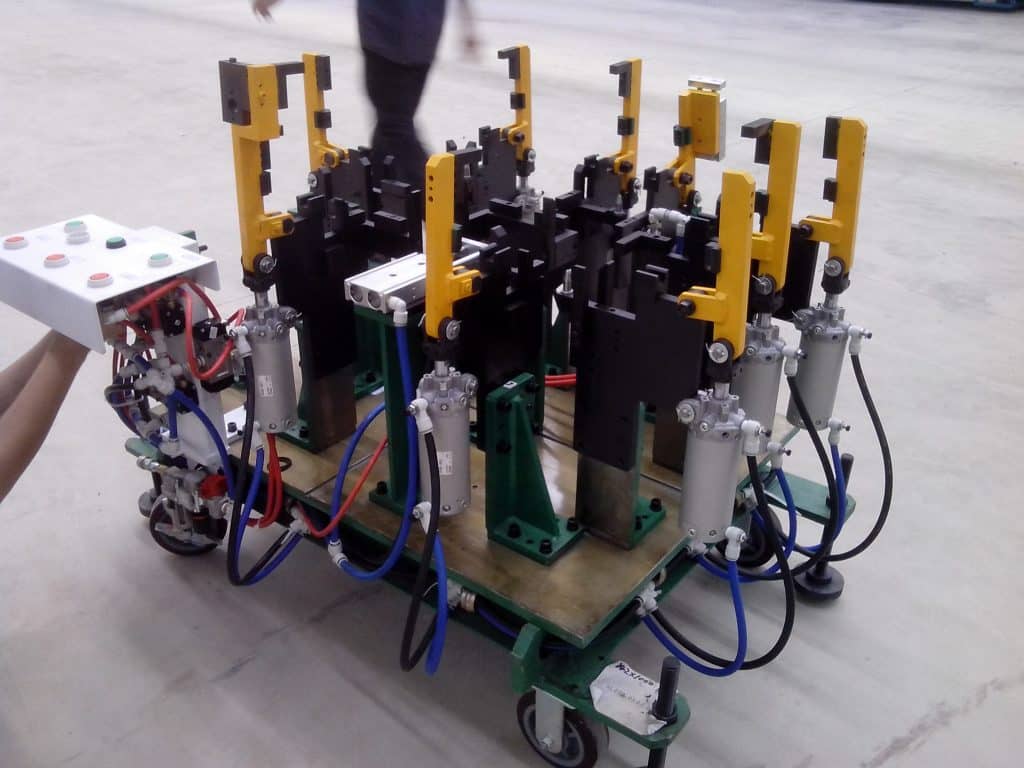

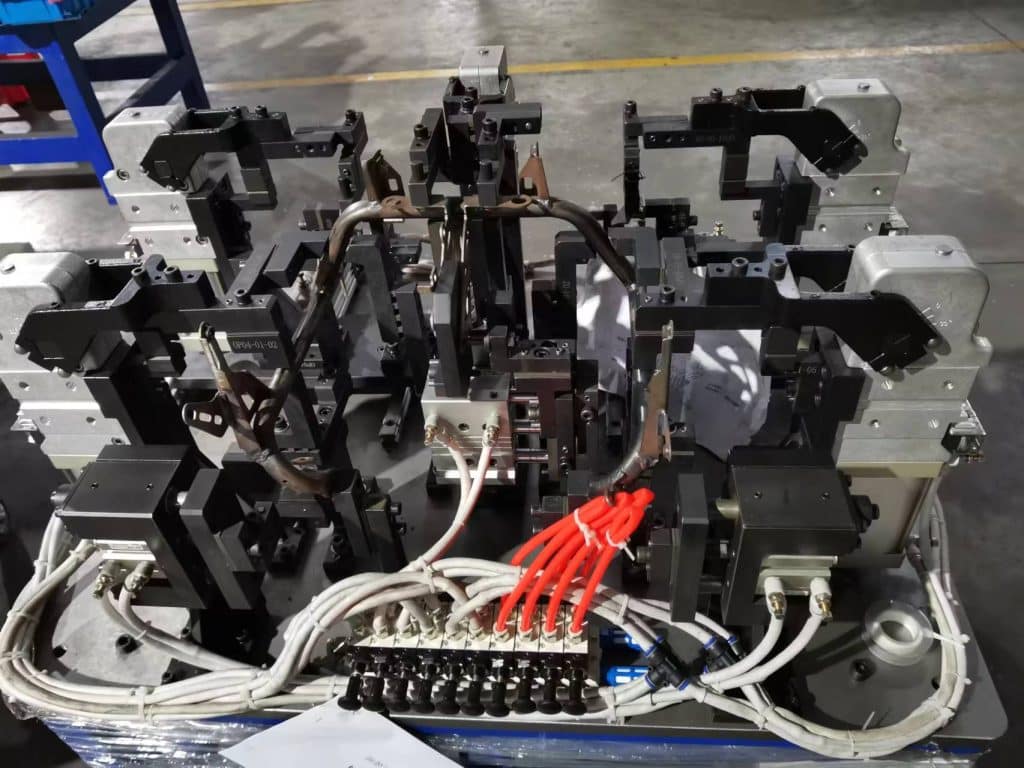

When precision matters, our welding jigs offer the stability and support needed for complex welding assemblies. Dragon Metal’s jigs are custom-built to hold your components in the right position, saving you time and ensuring consistent quality across every weld.

A well-designed jig reduces the need for manual adjustments, allowing for quicker setups and reliable positioning. With our welding jigs, you get:

Contact us to request a quote or learn more about how our welding jigs can optimize your production line. Our team is here to guide you to the perfect solution

Welding jigs are essential tools in manufacturing, designed to hold, support, or position materials during welding. They come in different types, each suited for specific tasks to enhance efficiency and precision. Below is an overview of common welding jigs and their uses:

Book-type jigs are ideal for handling materials like rolls or coils.

Rotators are designed to rotate parts around their axis.

Chain and roller jigs are specialized for loads with an uneven center of gravity.

Hydraulic jigs are designed for handling very heavy loads with the help of hydraulic drives.

Electric jigs bring automation to material handling tasks.

Not every welding job is the same, and our custom jigs are built to meet the unique demands of specialized projects. Whether you need unique angles, heights, or component holds, we’ll work with you to design and fabricate the perfect solution.