- Head Office: Brisbane, Australia

- AUS: 1800 333 182

- INT: +61 7 3369 6442

- Download Brochure

- ABN: 48 136 482 114

Dragon Metal offers several plastic moulding services, including plastic injection moulding, compression moulding, rotational moulding, plastic extrusion, blow moulding and more. We offer partial and full assembly of products with plastic and/or metal components and provide solutions that cover everything from raw material verification, tool making, moulding, surface finish and final inspection.

The most popular manufacturing process for producing a large quantity of the same plastic part. Plastic granules, usually in a liquid state, are heated up and injected under pressure into a mould cavity.

Rotional moulding is when a material charge or shot weight is placed inside a heated hollow mould, which is then slowly rotated (usually around two perpendicular axes). As the material softens, it spreads and adheres to the mould’s walls.

A large quantity of plastic is manufactured using an extrusion process, in which a polymer material is melted and formed continuously. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

Inflating or blowing a molten thermoplastic tube into the shape of a mould cavity creates a hollow object via blow moulding. This is most commonly used in the food industry to produce plastic bottles.

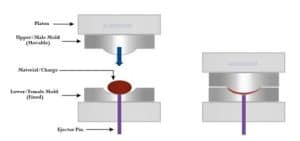

This process involves compressing materials under high pressure to form a desired shape. It is widely used in the manufacturing of plastic products. However, with the advent of new technologies and the increasing demand for metals, it is also being employed for metals, especially low carbon steels.

Selecting the right moulding process for your product can reduce your costs and increase your profits. Dragon Metal’s team of plastic moulding experts will help you decide which process is best for your product. We can also help you decide on the most suitable material for your product based on its properties and other factors such as post-processing techniques and coating. We offer a number of common plastic resins but are happy to source other material in China, Asia or even locally based on your project’s requirements.

Whether you are looking for a quick turnaround, low-cost manufacturing, or high quality, we can find a moulding partner for you. If you have a moulding need that is not listed above, let us know! We have connections with access to other plastic moulding techniques and are happy to help connect you with one of their factories.

Dragon Metal’s network involves a plethora of clients who trust in its ability to complete each project on time and pay attention to every detail. Our metal manufacturing team works according to Australian standards, and all our factories are ISO-9001 certified.

Our clients choose us because of three main reasons:

Transparency

Dragon Metal has built trust with all factories in its network, and it is entirely transparent with the chosen supplier. We encourage our customers to visit the selected Chinese factory so they can see where the plastic moulding process takes place and be present to approve the first samples and ensure everything is made to specification. Our engineers are always happy to work with our customers to optimize the production cycle and reduce time to market.

Confidentiality

Although Dragon Metal is entirely transparent with its suppliers, it offers contracts to ensure that customers’ information remains fully confidential. Before any data is passed around, Dragon Metal’s team makes sure each piece of confidential information is kept secure and all measures are taken to minimise any potential risk. All our contracts are covered by Australian law, so customers do not have to worry about their information not being safe and secure.

Customer Satisfaction

Our team takes care of each customer and offers full support throughout every step of the process, from first contact to beyond post-production. In fact, we are in it for the long run and aim to be our customers’ long-term manufacturing partner. We are always here for our customers, to listen to them, and make sure that our manufacturing processes exceed all expectations. With Dragon Metal’s unrivalled personal support, frictionless project management, and our quality guarantee, you will not only feel satisfied but also delighted.

The short answer – is yes.

Dragon Metal is proud of its confidentiality. Your metal manufacturing project’s intellectual property is always safe with us as we provide you with the best security and privacy possible. Our company is trusted by many Australian manufacturers, who know that we abide by strict confidentiality standards and protocols to protect all our customer IP, and who enjoy peace of mind knowing that their IP will remain confidential during the whole metal manufacturing process and beyond.

There are several ways you can get in touch with us at Dragon Metal; you can reach us by phone or via email at: enquiries@dragonmetal.com.au. Alternatively, you can also, visit our site and use our online chat or our contact form. If you fill out our online form, our representatives will get back to you within a few hours.

Find out how Dragon Metal can fulfil your manufacturing requirements and supplement your business.

Want to know more about our Metal Manufacturing Services? Read more in our Blog!