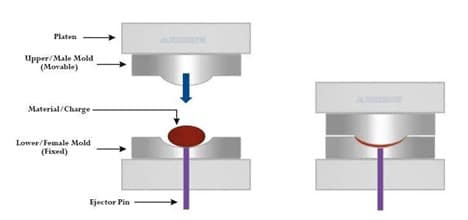

Compression molding is a pivotal manufacturing technique utilized for crafting diverse plastic or composite parts. The process entails introducing a pre-measured and preheated material, such as a thermosetting polymer or thermoplastic compound, into an open mold cavity. Subsequently, the mold is sealed, and

The world is facing a growing demand for energy as the population increases. However, the traditional sources of energy, such as fossil fuels, are running out and causing environmental problems. Therefore, we need to switch to renewable energy sources as soon as possible.

Metal fabrication has been an integral part of various industries, from automotive to construction, for decades. Ensuring the longevity and performance of metal components is crucial, and one way to achieve this is through inorganic coatings. In this article, we'll delve into the

Sheet metal fabrication is the process of transforming flat sheets of metal into different shapes and sizes using various tools and techniques. Sheet metal fabrication is widely used in many industries, but especially in the electronic industry, where precision, durability, and customization is

Chrome plating is a popular and versatile technique that can enhance the appearance and performance of various metal objects. Whether you want to give your car a shiny and sleek look or improve the durability and functionality of your industrial equipment, chrome plating

Laser cutting is a popular and versatile method of cutting metal into precise shapes and sizes. Laser cutting can produce complex and intricate designs with high accuracy and efficiency. But how does laser cutting work, and what are the different types of lasers

Die casting is a manufacturing technique that involves injecting molten metal into a mould and forming a desired shape under high pressure. Die casting is suitable for producing parts with complex designs that require accuracy and large-scale production. Some of the common metals

Hot dip galvanizing (HDG) is a widely used method of protecting steel from corrosion by coating it with a layer of zinc. The thickness of the galvanized coating is important for the durability and performance of the steel in different environments. In this

Plastic extrusion is a manufacturing process that involves melting and shaping plastic materials into continuous profiles. Plastic extrusion can produce a wide range of products, such as pipes, tubes, hoses, sheets, films, rods, profiles, and more. Plastic extrusion is widely used in various

The automotive industry is one of the most demanding and competitive sectors in the world, requiring high-quality, durable, and reliable components for various applications. One of the methods that can produce such parts is forging, a process that involves shaping metal using compressive