Metal Laser Cutting Basics: Materials and Types of Lasers Used

Laser cutting is a popular and versatile method of cutting metal into precise shapes and sizes. Laser cutting can produce complex and intricate designs with high accuracy and efficiency. But how does laser cutting work, and what are the different types of lasers

How Offshore Manufacturing Solves Capacity Issues?

If you are a manufacturer, you may have faced capacity issues at some point in your business. In the world of manufacturing, meeting production capacity requirements while maintaining efficiency and quality standards can be a challenging endeavour. Businesses often grapple with the need

What is Contract Manufacturing? How Does it Work?

Contract manufacturing is a type of outsourcing that companies use, which involves hiring a manufacturer to create products. A contract manufacturer may take part in various stages of production, including design, manufacturing, and shipping, depending on the needs of their client. In this

Zinc vs Aluminium Die Casting: Quality Comparison

Die casting is a manufacturing technique that involves injecting molten metal into a mould and forming a desired shape under high pressure. Die casting is suitable for producing parts with complex designs that require accuracy and large-scale production. Some of the common metals

Coating Thickness for Hot Dip Galvanizing

Hot dip galvanizing (HDG) is a widely used method of protecting steel from corrosion by coating it with a layer of zinc. The thickness of the galvanized coating is important for the durability and performance of the steel in different environments. In this

Importance of Supply Chain Diversification in Manufacturing Industry

Supply chain diversification is the practice of sourcing materials, components, and services from a variety of suppliers, locations, and markets. It is a strategic approach to managing supply chain risks and enhancing competitiveness in the manufacturing industry. Supply chains are vital for the

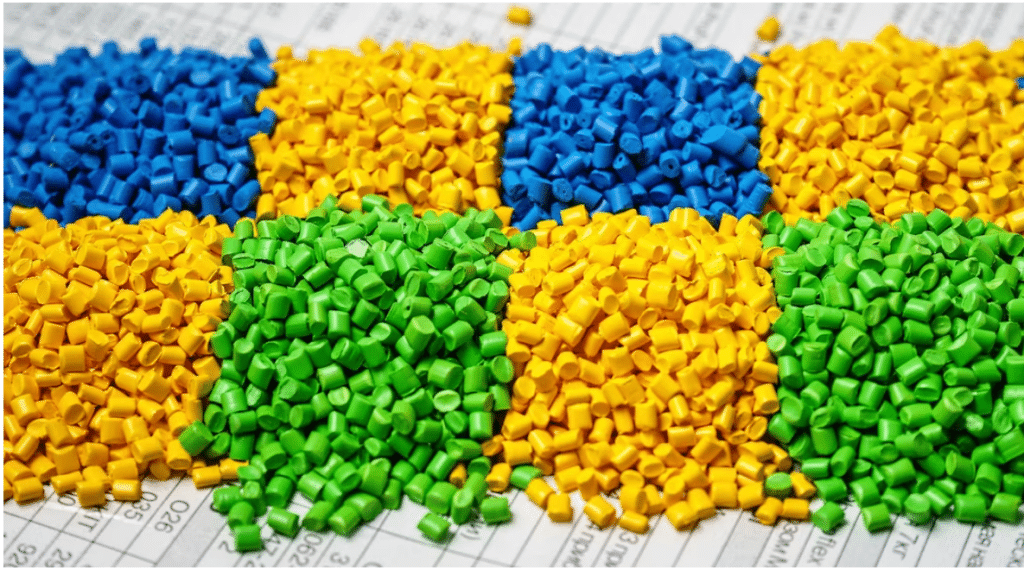

Key Types of Plastic Extrusion Materials

Plastic extrusion is a manufacturing process that involves melting and shaping plastic materials into continuous profiles. Plastic extrusion can produce a wide range of products, such as pipes, tubes, hoses, sheets, films, rods, profiles, and more. Plastic extrusion is widely used in various

Asian Manufacturing Supply Chain: Emerging Hubs

Many businesses rely on Asian manufacturing supply chain to produce and deliver their goods and services. A supply chain is a network of activities, people, and resources that starts with raw materials and ends with finished products in the hands of customers. A

Choosing Right Shipping Method for Offshore Manufacturing

If you are involved in offshore manufacturing, you know how important it is to choose the right shipping method for your products or parts. Shipping can have a significant impact on your costs, profits, customer satisfaction, and environmental footprint. But how do you

Forging Metal Parts for Automotive Excellence

The automotive industry is one of the most demanding and competitive sectors in the world, requiring high-quality, durable, and reliable components for various applications. One of the methods that can produce such parts is forging, a process that involves shaping metal using compressive

Metal Stamping Process and Innovative Application

The history of metal stamping traces its origins back to the industrial revolution, when it emerged as a revolutionary cold forming technique primarily used to manufacture bicycle frames and handlebars. Rooted in Germany, this method has since evolved into an indispensable cornerstone of

When Should a Company Decide to Take Manufacturing Offshore?

The globalization of markets and the rapid advancement of technology have reshaped the way businesses operate and make strategic decisions. One such pivotal choice that companies often grapple with is whether to shift their manufacturing operations offshore. This decision holds profound implications for